In today’s industrial world, precision, efficiency, and eco-friendly solutions are vital for metal processing and restoration. One technology that has transformed the way industries maintain and prepare surfaces is laser cleaning metal. Mart Laser stands at the forefront of this revolution, delivering advanced laser cleaning systems designed for businesses that require reliable, non-destructive, and cost-effective surface cleaning.

What is Laser Cleaning Metal?

Laser cleaning metal is a modern method that uses high-energy laser beams to remove rust, paint, oil, and other unwanted contaminants from metal surfaces. Unlike abrasive methods such as sandblasting or chemical cleaning, this process leaves the base metal intact and free from damage. It is fast, safe, and environmentally friendly, making it the preferred choice for industries ranging from automotive and aerospace to shipbuilding and heavy machinery.

Why Industries Choose Mart Laser

Mart Laser provides state-of-the-art machines that are built for long-term performance and high precision. Their laser cleaning systems are designed to handle even the toughest contaminants while ensuring smooth operation. With adjustable settings, users can control the intensity of cleaning, making it suitable for delicate applications like heritage restoration or heavy-duty projects such as rust removal from ship hulls.

Another reason industries rely on Mart Laser is its commitment to sustainability. Traditional cleaning often involves chemicals that harm the environment. In contrast, Mart Laser’s systems work with no consumables and minimal waste, making them a green alternative that reduces overall operating costs.

Applications of Mart Laser Cleaning Technology

Mart Laser’s laser cleaning metal solutions are versatile and widely used in:

-

Rust removal: Quickly restores metal parts to their original condition without grinding or damage.

-

Paint stripping: Effectively removes coatings for repainting or refurbishment.

-

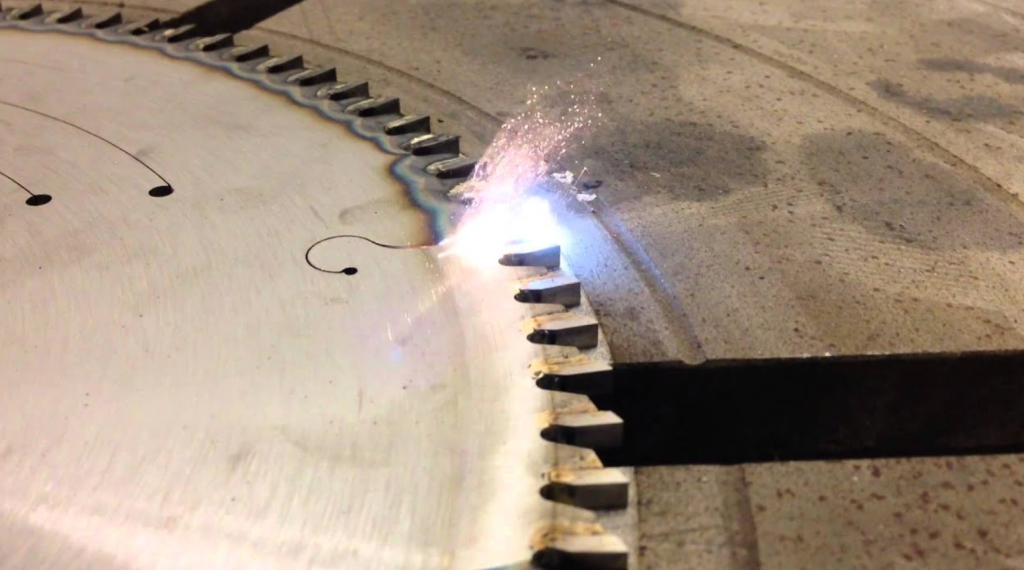

Welding preparation: Cleans surfaces before welding to improve bonding quality.

-

Oil and grease removal: Ensures metal parts are free from residues before machining.

-

Cultural heritage preservation: Cleans old statues, artifacts, and metal structures safely.

These diverse applications show why Mart Laser is trusted across multiple sectors.

Partnering with Mart Laser

When choosing a provider for laser cleaning metal systems, reliability and expertise matter. Mart Laser not only delivers cutting-edge technology but also provides full technical support, training, and customization to meet specific industrial needs. Their customer-focused approach ensures smooth integration of laser cleaning systems into your workflow.

With Mart Laser, businesses gain a powerful partner that helps them improve efficiency, reduce downtime, and embrace sustainable technology.

Conclusion

The demand for laser cleaning metal solutions continues to rise as industries search for cleaner, faster, and more cost-effective methods. Mart Laser leads this movement by providing advanced machines that set new standards in metal cleaning technology. Whether it’s for manufacturing, restoration, or maintenance, Mart Laser delivers the perfect balance of performance and innovation.