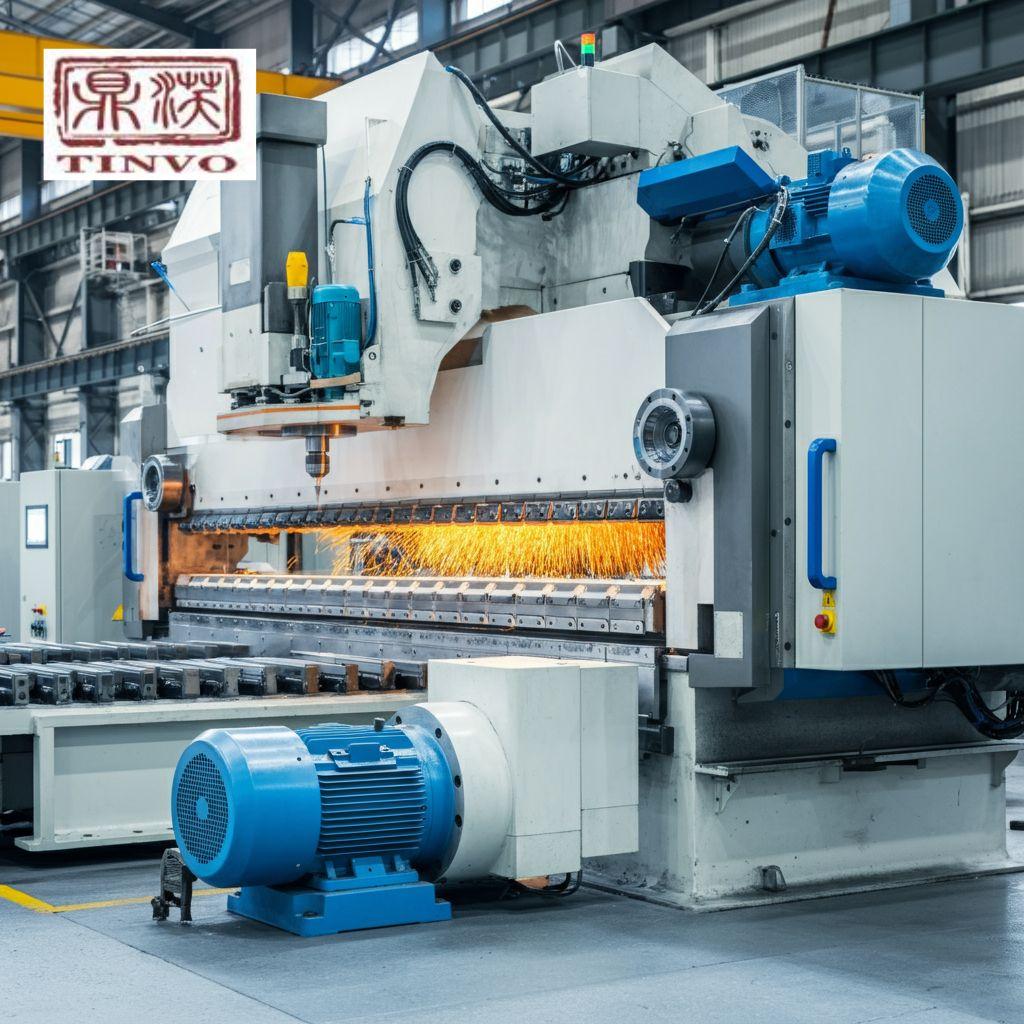

Efficiency and precision are two cornerstones of modern high-speed production lines. Whether shaping materials for construction, manufacturing machinery, or consumer goods, each component plays a vital role in achieving consistent quality and maximum productivity. Among these essential components is the Flying Shear Blade, an indispensable tool for precision cutting in industries processing metal and other durable materials.

Flying Shear Blades are designed for high-speed operations, offering unmatched accuracy and reliability. They are essential in cutting applications, enabling smooth workflows without halting the production process. This article explores the importance, functionality, and complementary mechanisms that enhance these blades’ capabilities, while highlighting why TinvoGroup is the trusted name in supplying high-quality Flying Shear Blades and related machinery.

The Importance of Flying Shear Blades in Production

Precision at High Speeds

The Flying Shear Blade is engineered to maintain precision during high-speed cutting operations without compromising on accuracy or material integrity. These blades ensure that the cutting process doesn't interrupt the flow of materials on the production line, minimizing downtime and maintaining productivity rates.

High-speed production lines—especially those in steel and metal industries—demand equipment capable of handling enormous stress while delivering impeccable results. By precisely cutting materials like steel, aluminum, and other metals to the desired sizes, Flying Shear Blades play a major role in reducing waste and meeting tight tolerances.

Impact on Cost Efficiency

Effective metal cutting is not just about precision—it’s about optimizing material usage and reducing operational costs. Flying Shear Blades significantly contribute to cost efficiency by:

- Reducing the amount of wasted material.

- Minimizing energy consumption with smooth, high-efficiency cutting techniques.

- Lowering maintenance costs, thanks to their durable construction and reliability.

Production lines rely on these blades to meet customer demands for both speed and accuracy in industries where consistency is non-negotiable.

How Flying Shear Blades Work

The Flying Shear Blade operates by synchronizing its cutting motion with the speed of the material moving on the production line. This synchronization allows it to make precise cuts without requiring the material to stop. The integration of technological advancements, such as automated controllers, ensures seamless coordination.

The functionality of Flying Shear Blades is often enhanced by accompanying machinery and components. TinvoGroup excels in providing not only the blades but also advanced mechanisms that enable their optimal performance.

Supporting Mechanisms

Reduction Gearbox

A Reduction Gearbox assists in managing the high torque generated during cutting activities. By reducing the speed of the gears and enhancing torque output, these gearboxes ensure proper blade functionality even under extreme operational stress. TinvoGroup’s reduction gearboxes are meticulously engineered to work in tandem with Flying Shear Blades, enabling superior performance and longevity.

Herringbone Gear

Known for its robust design, the Herringbone Gear is critical in mitigating axial load and ensuring smooth motion. This gear type complements the blade’s movement, reducing vibration and wear. TinvoGroup integrates high-quality herringbone gears into their systems to further enhance cutting precision and operational stability.

Single Helical Gear

The Single Helical Gear provides excellent load distribution and smooth motion transfer, ensuring consistent blade operation. TinvoGroup’s expertise in manufacturing these gears guarantees compatibility with high-speed production setups, reinforcing performance reliability.

Straightening Machine

After materials are cut, a Straightening Machine often comes into play, ensuring that the materials align perfectly for the next stage of processing. TinvoGroup offers a range of straightening machines designed to handle the unique demands of high-speed production lines, providing a seamless transition between cutting and subsequent operations.

Benefits of Flying Shear Blades for Metalworking

Durability and Strength

Crafted from high-quality materials, Flying Shear Blades are highly durable, making them capable of withstanding the intense pressures of industrial applications. They can handle rigorous, continuous operation, maintaining their sharpness and efficiency over extended periods.

Versatility for Various Industries

Industries such as automotive manufacturing, construction, and metal fabrication benefit immensely from the versatility of Flying Shear Blades. TinvoGroup's blades offer adaptability to meet the diverse needs of different applications, ensuring top-tier results regardless of the specific cutting requirements.

Seamless Integration

One of the key benefits of Flying Shear Blades lies in their seamless integration with advanced gear systems and supporting machinery, all of which TinvoGroup provides. Their solutions are designed for compatibility, ensuring effortless assembly and reduced lead times during installation and upgrades.

Why Choose TinvoGroup?

Expertise and Innovation

TinvoGroup is recognized as a leader in manufacturing and supplying Flying Shear Blades and related equipment. Their extensive experience and focus on innovative solutions make them a trusted partner for high-speed production lines. They understand the unique demands of industrial applications and consistently deliver products that exceed industry standards.

Comprehensive Product Range

Beyond supplying Flying Shear Blades, TinvoGroup offers a full suite of supporting components, including Reduction Gearboxes, Herringbone Gears, Single Helical Gears, and Straightening Machines. These products are meticulously crafted for superior compatibility, performance, and longevity.

Commitment to Quality

TinvoGroup is committed to providing products that stand the test of time. Using premium-quality materials and state-of-the-art manufacturing processes, their offerings ensure efficient operation, cost-effectiveness, and reduced downtime for production lines.

Tailored Solutions

Recognizing that no two production lines are the same, TinvoGroup offers customized solutions to meet specific operational needs. From high-speed cutting requirements to unique material specifications, TinvoGroup ensures their products deliver exactly what each client needs for optimal productivity.

Final Thoughts

The Flying Shear Blade is a pivotal tool for high-speed production lines, enabling precision cutting and operational efficiency in a wide range of industries. Enhanced by components such as Reduction Gearboxes, Herringbone Gears, Single Helical Gears, and Straightening Machines, these blades ensure smooth workflows and cost-effective production. TinvoGroup stands out as an industry leader, offering top-quality products and unmatched expertise to keep production lines running at peak performance.

When it comes to precision cutting tools and complementary machinery, TinvoGroup's commitment to innovation and customer satisfaction makes them the ideal partner for industries worldwide. Equip your production line with the excellence of TinvoGroup and experience smoother, more efficient operations today.