Creating accurate and detailed shop drawings for wall panels is a crucial part of the construction and manufacturing process. However, traditional methods can be time-consuming, prone to errors, and often lead to project delays.

Streamlining your wall panel shop drawing process not only saves time and resources but also improves precision and coordination among project stakeholders.

In this article, we will explore practical strategies and modern tools that can help you optimize your drawing workflow, reduce errors, and ultimately deliver high-quality wall panel designs more efficiently.

Understanding Wall Panel Shop Drawings

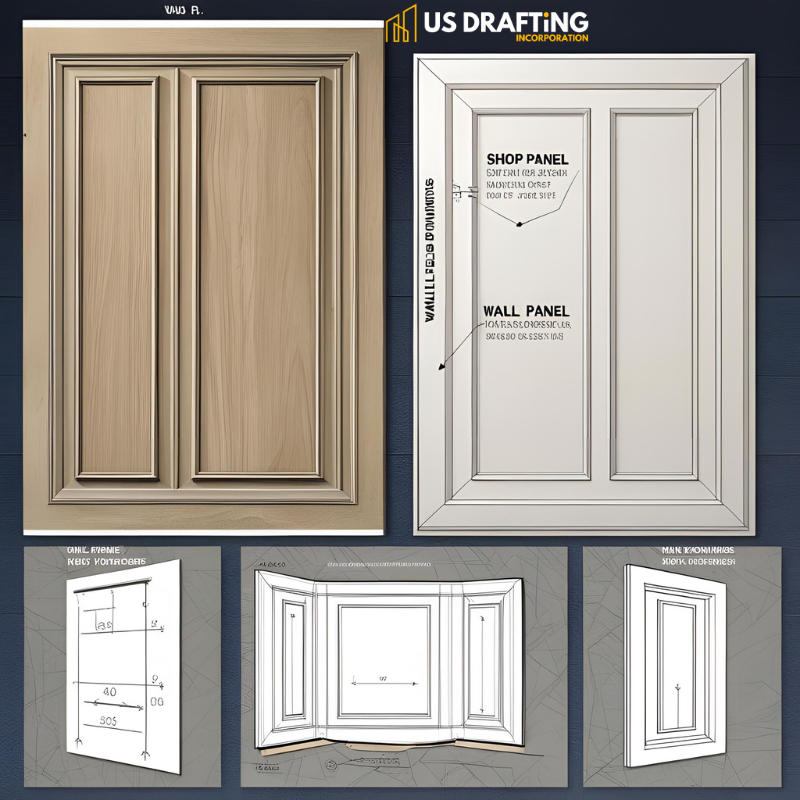

Wall panel shop drawings are detailed diagrams created to guide the manufacturing and installation of wall panels in construction projects. These drawings are essential for architects, engineers, contractors, and fabricators, as they ensure that the panels are built and installed correctly.

Typically, wall panel shop drawings include precise measurements, material specifications, connection details, and installation instructions. They may also show how the panels fit within the overall structure. These drawings help to visualize the panel’s shape, size, and placement, minimizing errors during production and installation.

One of the key purposes of wall panel shop drawings is to bridge the gap between architectural designs and actual construction. While architectural plans give a general idea, shop drawings break down the specific details needed to fabricate each panel. This includes showing where windows, doors, or other openings are located within the panel.

Contractors use these drawings to ensure that the panels are manufactured to the correct specifications. Fabricators follow them to cut and assemble the panels accurately. During installation, the drawings act as a reference to make sure the panels are placed in the right position and orientation.

Moreover, shop drawings undergo a review process where architects and engineers check for accuracy and compliance with the design intent. Any discrepancies can be addressed before production begins, saving time and costs.

Common Challenges in Wall Panel Shop Drawing Process

The wall panel shop drawing process plays a crucial role in construction, as it provides detailed plans for prefabricated wall panels. However, this process is not without challenges.

One of the most common challenges is inaccurate measurements. Even a minor mistake can lead to panels that do not fit properly during installation. To avoid this, precise measurements and double-checking are essential.

Another issue is poor communication among stakeholders. Designers, engineers, and fabricators need to be on the same page. Miscommunication can result in discrepancies between the design intent and the final product. Regular collaboration and clear documentation help reduce this risk.

Design changes are also challenging. As projects evolve, updates to the wall panel drawings may be needed. Keeping track of revisions and ensuring that all parties are aware of changes can be difficult. Using version control systems can help manage these updates effectively.

Material selection and availability can also cause issues. Sometimes, the specified materials are not available, leading to delays or the need for substitutions. Planning for alternatives can help mitigate this problem.

Lastly, quality control is crucial. Errors in the drawing can lead to defects in the fabricated panels. Implementing a thorough review process before finalizing drawings helps catch mistakes early.

Addressing these challenges requires careful planning, collaboration, and quality assurance. By focusing on accuracy and communication, teams can produce reliable wall panel shop drawings that streamline the construction process.

Benefits of Streamlining the Drawing Process

Streamlining the drawing process means making it faster and more efficient. This approach has many benefits, especially for artists, designers, and anyone involved in creating visual content.

One of the most significant advantages is saving time. By organizing tools and techniques, artists can work more quickly without compromising quality. For example, using digital templates or preset brushes can reduce repetitive tasks, allowing creators to focus more on creativity.

Streamlining also helps improve consistency. When drawing regularly, maintaining a consistent style is essential, especially in projects like animation or comic series. Having a clear process ensures that the final product looks uniform and professional.

Another benefit is reduced stress. A simplified process makes it easier to complete tasks without feeling overwhelmed. Knowing which steps to follow can help artists feel more confident and less pressured.

Moreover, it boosts productivity. When the drawing process is well-organized, creators can complete more projects in less time. This efficiency is valuable for professionals working with tight deadlines or multiple assignments.

Finally, streamlining encourages skill development. By focusing on core techniques and eliminating unnecessary steps, artists can practice and improve specific skills. Over time, this leads to better quality and more refined artwork.

In summary, streamlining the drawing process saves time, ensures consistency, reduces stress, increases productivity, and helps artists develop their skills. Adopting this approach can make the creative journey more enjoyable and efficient.

Steps to Streamline Your Wall Panel Shop Drawing Process

Creating accurate and efficient wall panel shop drawings is crucial for construction projects. Streamlining this process can save time, reduce errors, and improve overall productivity. Here are some effective steps to achieve this.

First, adopt the right technology. Using advanced CAD software or BIM (Building Information Modeling) tools can greatly enhance your drawing process. These tools offer precise measurements, easy modifications, and integration with other project data, making your workflow faster and more accurate.

Next, standardize your drawing templates and symbols. Consistency in templates helps your team maintain uniformity across all drawings. Use standard symbols and notations to reduce confusion and ensure everyone understands the details.

Automating repetitive tasks is another way to boost efficiency. Many software solutions allow you to automate tasks like dimensioning, labeling, and generating schedules. By minimizing manual input, you can focus more on design and quality.

Improving collaboration and communication among team members is equally important. Use cloud-based platforms where designers, engineers, and stakeholders can access, review, and update drawings in real time. This reduces delays and keeps everyone on the same page.

Lastly, establish a quality control process. Regularly review your drawings to catch errors before they reach the construction site. Implementing checklists and peer reviews can help maintain accuracy and quality.

Streamlining the wall panel shop drawing process is essential for enhancing productivity, reducing errors, and ensuring project success. By leveraging advanced technology, standardizing templates, automating repetitive tasks, fostering collaboration, and implementing quality control measures, construction teams can significantly improve efficiency. Addressing common challenges with proactive strategies not only saves time and resources but also promotes better communication among stakeholders. Ultimately, a well-organized drawing process leads to high-quality wall panel designs, smoother production, and successful project outcomes.

The Final Note

Streamlining the wall panel shop drawing process is essential for enhancing productivity, reducing errors, and ensuring project success. By leveraging advanced technology, standardizing templates, automating repetitive tasks, fostering collaboration, and implementing quality control measures, construction teams can significantly improve efficiency.

Addressing common challenges with proactive strategies not only saves time and resources but also promotes better communication among stakeholders. Ultimately, a well-organized drawing process leads to high-quality wall panel designs, smoother production, and successful project outcomes.