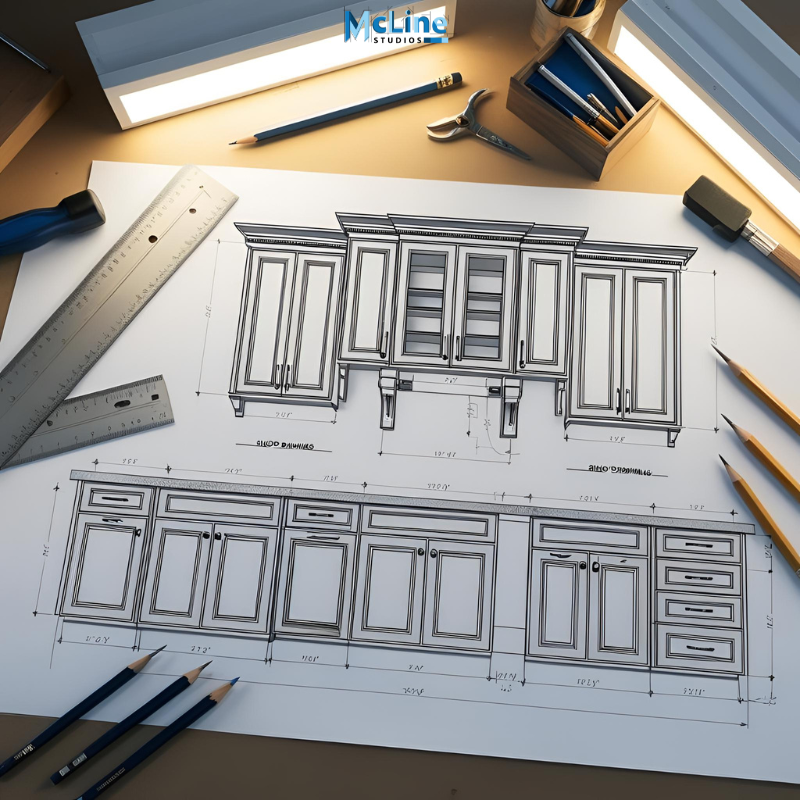

Millwork shop drawings are the blueprint for high-quality custom woodwork, ensuring precision, efficiency, and seamless execution. Whether you're a contractor, architect, designer, or fabricator, understanding how to read and interpret these drawings is essential for translating design concepts into reality.

These detailed technical documents provide comprehensive information on materials, dimensions, construction methods, and finishes, acting as a communication bridge between designers and manufacturers. Misinterpreting a millwork shop drawing can lead to costly errors, delays, and rework, making it crucial to master the skill of reading them accurately.

In this guide, we’ll break down the key elements of millwork shop drawings, explain industry-standard symbols and notations, and share expert tips to help you analyze them like a pro. Whether you’re new to the field or looking to refine your skills, this article will equip you with the knowledge needed to navigate millwork drawings with confidence.

Understanding the Basics of Millwork Shop Drawings

Millwork shop drawings are detailed technical drawings that show how custom woodwork elements, like cabinets, doors, and paneling, should be built and installed. These drawings act as a bridge between design ideas and actual construction, ensuring accuracy and consistency in the final product.

A millwork shop drawing typically includes precise dimensions, material specifications, joinery details, and installation instructions. It serves as a guide for manufacturers, architects, and contractors, helping them understand every aspect of the project before production begins.

One key feature of these drawings is their high level of detail. They show different views, such as front, side, and top, to give a complete picture of the millwork piece. They may also include section views, which cut through a part of the design to show internal details. Additionally, annotations and notes explain finishes, hardware, and any special features.

Creating accurate millwork shop drawings is essential to avoid mistakes during manufacturing and installation. Errors in measurements or unclear instructions can lead to costly delays and material waste. That’s why skilled drafters use specialized software like AutoCAD or Revit to create precise and clear drawings.

Millwork shop drawings help maintain quality, improve communication between teams, and ensure that the final product matches the original vision. Whether for residential or commercial projects, these drawings play a crucial role in bringing custom woodwork designs to life efficiently and professionally.

Common Symbols and Conventions in Millwork Drawings

Millwork drawings use specific symbols and conventions to communicate details clearly to architects, designers, and manufacturers. These standard symbols help avoid confusion and ensure accuracy in construction.

One of the most common symbols in millwork drawings is the dimension line, which shows the measurements of different parts. Arrows at the ends indicate the start and end points. Hidden lines, usually dashed, represent elements that are not visible in a particular view, such as internal shelves or supports.

Section markers are used to indicate where a cross-sectional view is provided for better understanding. These sections help visualize details like wood joinery, edge profiles, or interior structures. Elevation markers show the front, side, or rear views of a millwork piece.

Different materials are also represented by standard hatch patterns. For example, wood may have a specific pattern, while glass, metal, and stone have distinct symbols. Grain direction arrows indicate how wood grain should run, which affects both aesthetics and durability.

Letter and number codes help organize the drawings. For instance, cabinets might be labeled as "CAB-01", drawers as "DRW-02", and moldings as "MLD-03". These labels make it easy to identify components in larger projects.

Understanding these symbols ensures smooth communication between designers and fabricators. By following conventions, millwork drawings become precise and easy to read, reducing errors in manufacturing and installation.

Breaking Down a Millwork Drawing: Step-by-Step Interpretation

Millwork drawings are essential for turning design ideas into real, high-quality woodwork. Whether you're working on cabinetry, molding, or custom furniture, understanding these drawings is key. Here’s a simple breakdown of how to interpret them.

- Title Block

Start by looking at the title block. It contains important details like project name, date, drawing number, scale, and the designer’s or company’s name. - Views and Sections

Millwork drawings include different views to show all sides of the piece. The plan view (top-down), elevation view (front or side), and section view (cut-through) help you understand dimensions and details. - Dimensions and Measurements

Check the measurements carefully. These include width, height, depth, and thickness. Every detail matters to ensure a perfect fit. - Materials and Finishes

The drawing often specifies materials like wood type, laminates, or veneers, along with finishes such as paint, stain, or varnish. - Joinery and Hardware Details

Look for symbols and notes indicating joints (dovetail, dowel, or mortise and tenon) and hardware like hinges, handles, and drawer slides. - Notes and Legends

Finally, read any additional notes or legends that explain special instructions or assembly steps.

By carefully studying these elements, you can accurately interpret a millwork drawing and ensure smooth manufacturing and installation.

Practical Tips for Reading Millwork Shop Drawings Like a Pro

Millwork shop drawings are detailed blueprints that guide the construction and installation of custom woodwork, such as cabinets, doors, and trim. Understanding these drawings is key to ensuring accuracy and avoiding costly mistakes. Here are some practical tips to read them like a pro:

1. Understand the Symbols and Notations

Millwork drawings use industry-standard symbols, abbreviations, and line types. Take time to learn what each symbol represents, such as materials, finishes, and joinery details. A legend or key is usually included in the drawing for reference.

2. Familiarize Yourself with the Views

Most shop drawings include multiple views—plan, elevation, and section. The plan view shows a top-down layout, the elevation view displays a straight-on perspective, and the section view provides a cut-through look at internal details. Understanding how these views connect will help you visualize the final product.

3. Pay Attention to Dimensions

Every measurement matters. Check dimensions carefully, including width, height, and depth. Compare them with the project specifications to ensure they align with site conditions.

4. Identify Materials and Finishes

Millwork drawings often specify wood species, veneers, laminates, and finishes. Verify that these match the design requirements and are suitable for the environment.

5. Look for Hardware and Assembly Details

Details about hinges, fasteners, and joints are included in the drawings. Understanding these helps with accurate fabrication and installation.

By following these tips, you can confidently interpret millwork shop drawings and contribute to a smooth and successful project!

Tools and Software for Viewing and Analyzing Millwork Drawings

Millwork drawings are essential for precision in woodworking projects, helping designers, manufacturers, and installers stay on the same page. To view and analyze these detailed drawings effectively, professionals use various tools and software.

CAD Software

Computer-Aided Design (CAD) software like AutoCAD, SolidWorks, and MicroStation allows users to create, edit, and review millwork drawings in 2D and 3D formats. These tools help in making precise measurements, detecting errors, and ensuring accurate designs before production.

BIM Software

Building Information Modeling (BIM) tools such as Revit and ArchiCAD provide a more detailed look at millwork elements within an entire building structure. These tools are useful for large projects, allowing real-time collaboration and better coordination with architects and engineers.

PDF Viewers and Markup Tools

Many millwork drawings are shared in PDF format for easy access. Software like Bluebeam Revu and Adobe Acrobat allows users to view, annotate, and measure drawings without needing a CAD program. These tools help teams communicate changes efficiently.

Cloud-Based Collaboration Platforms

Platforms like Autodesk BIM 360, PlanGrid, and Trimble Connect allow teams to access and review millwork drawings from any device. These tools improve collaboration, reduce errors, and keep everyone updated with the latest drawing versions.

Using the right tools ensures accuracy, saves time, and improves efficiency in millwork drafting and production. Choosing the best software depends on project needs, team size, and budget.

The End Note

Mastering the skill of reading and interpreting millwork shop drawings is essential for ensuring precision, efficiency, and seamless execution in custom woodworking projects. By understanding the key components—such as title blocks, views, dimensions, materials, and joinery details—you can confidently analyze these technical documents and minimize errors.

Familiarizing yourself with standard symbols and conventions, along with using the right tools and software, further enhances accuracy and collaboration between designers, fabricators, and contractors.

Whether you’re a seasoned professional or new to millwork drafting, honing your ability to interpret these drawings will improve project outcomes, reduce costly mistakes, and bring design concepts to life with precision.

By applying the insights and techniques shared in this guide, you’ll be well-equipped to navigate millwork shop drawings like a pro and contribute to the successful completion of high-quality custom woodwork projects.