The financial graveyard of the construction industry is filled with projects that started with optimism and ended in litigation. The primary cause of death is rarely a catastrophic engineering failure or a natural disaster. It is almost always a failure of the budget. In the high-stakes world of development, a budget is not merely a spreadsheet or a regulatory requirement. It is the definitive roadmap for the entire venture. If the map is wrong, the destination will never be reached.

A "bulletproof" budget is one that withstands the inevitable shocks of the real world. It absorbs price fluctuations, schedule delays, and design changes without collapsing. Creating such a budget requires more than just guessing numbers or relying on historical averages. It requires a rigorous, data-driven methodology that accounts for every variable. This article outlines the engineering and management principles necessary to construct a financial plan that reflects reality, ensuring your next construction project remains profitable from groundbreaking to handover.

The Foundation: Work Breakdown Structure (WBS)

You cannot price what you cannot define. The most common error in budgeting is ambiguity. A line item that simply says "Electrical Works: $500,000" is a recipe for disaster. It hides a multitude of potential costs and scope gaps.

To build a robust budget, you must first build a detailed Work Breakdown Structure (WBS). This involves deconstructing the entire construction project into its smallest distinct components. You do not just list "Concrete." You list excavation, rebar supply, rebar installation, formwork rental, concrete pumping, pouring, curing, and finishing.

By breaking the project down to this granular level, you expose the hidden costs. You realize that the "Concrete" line item needs to include the cost of the crane to lift the bucket and the cost of the testing laboratory to verify the strength. The WBS forces you to think through the construction sequence step by step. If a task exists in the real world, it must have a corresponding line in the budget. If it is not on the list, it will eventually become a cost overrun.

Differentiating Hard Costs and Soft Costs

Amateur developers often focus entirely on "Hard Costs." These are the tangible expenses: bricks, mortar, steel, labor, and machinery. While these make up the bulk of the expenditure, they are not the whole picture. Ignoring "Soft Costs" is a primary reason why a construction project runs out of cash before completion.

Soft costs are the intangible expenses required to deliver the project. In complex markets like Dubai, these can amount to 30% of the total budget. They include:

- Design and Engineering Fees: Architects, structural engineers, MEP consultants, and specialty designers.

- Permits and Government Fees: Approvals from the Municipality, Civil Defense, and utility providers often come with significant price tags.

- Legal and Financial Costs: Insurance premiums, loan interest, and legal retainers for contract drafting.

- Project Management Fees: The cost of the team overseeing the work.

A bulletproof budget separates these two categories clearly. It acknowledges that soft costs often need to be paid upfront, long before construction begins. failing to allocate sufficient cash for these early expenses can stall the project before the first shovel hits the ground.

The Science of Contingency

A contingency fund is not a "slush fund" or a sign of poor planning. It is a statistical necessity. In any construction project, there are "Known Unknowns" and "Unknown Unknowns." You know that weather might delay the pour, but you do not know when. You know that material prices might fluctuate, but you do not know by how much.

A professional budget includes tiered contingencies.

- Design Contingency: Used during the design phase. As the drawings evolve from concept to detailed design, the scope often expands. This contingency (typically 5% to 10%) covers this evolution.

- Construction Contingency: Used during the build phase. This covers unforeseen site conditions, such as finding bad soil or hitting an unmapped utility pipe (typically 5% to 10%).

- Owner's Contingency: A reserve held by the client for scope changes they might initiate later, like upgrading the lobby finishes.

Do not make the mistake of having a single 5% contingency line at the bottom. It will be consumed immediately. Allocate specific contingencies to specific risk categories to maintain control.

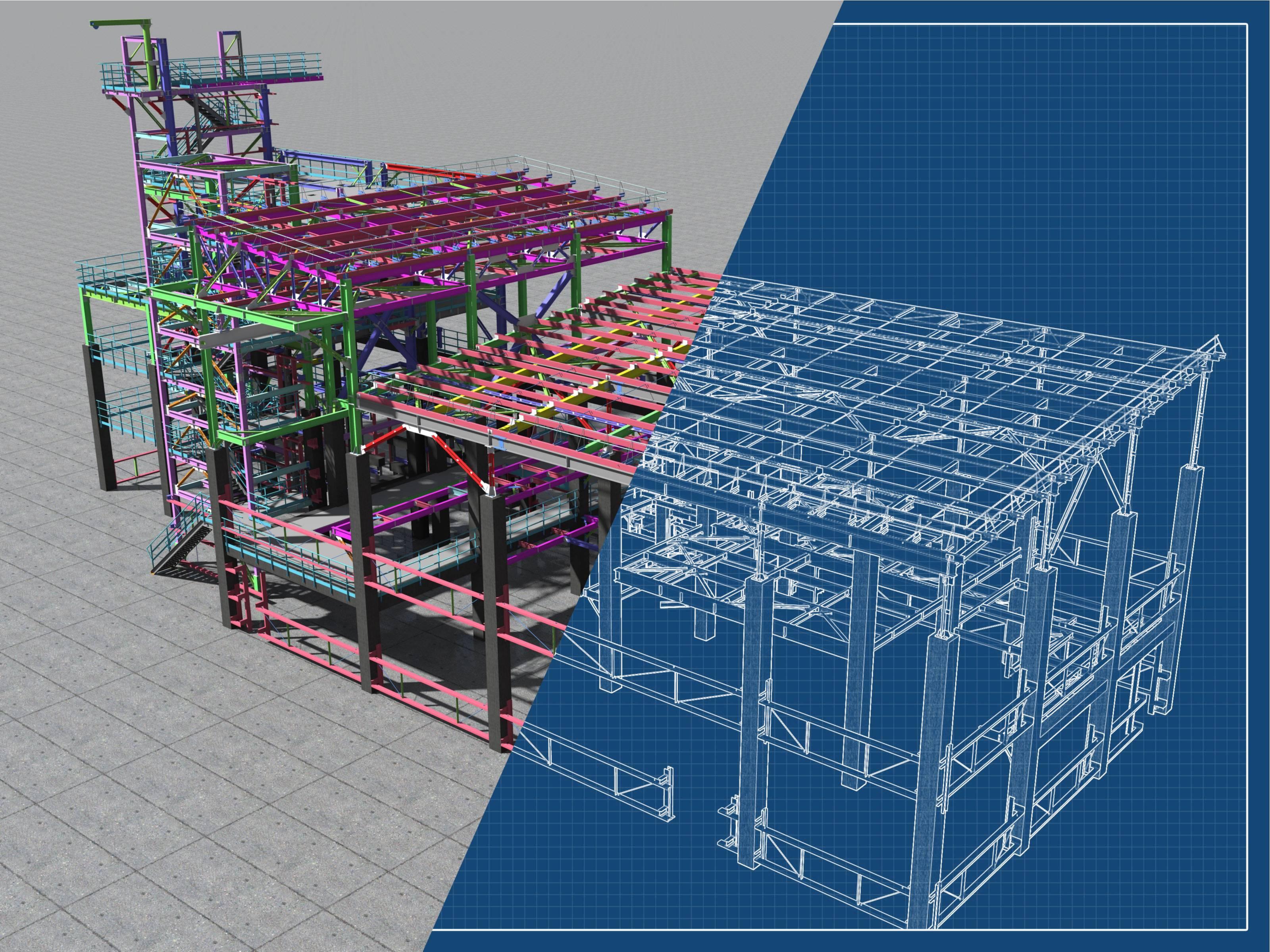

Leveraging 5D BIM for Precision

Traditional estimating relies on manual "quantity take-offs." A surveyor uses a scale ruler on 2D plans to measure the length of walls and the area of floors. This process is slow and prone to human error. If the surveyor misses a set of beams on page 45, the budget is short by thousands of dollars.

Modern budgeting utilizes 5D Building Information Modeling (BIM). In this workflow, the budget is linked directly to the 3D design model. The software calculates the quantities automatically. It knows exactly how many cubic meters of concrete are in the structure because it calculates the volume of the geometry.

If the design changes, the budget updates instantly. This creates a dynamic link between design and cost. It allows you to run scenarios. "What happens to the budget if we change the facade from aluminum to stone?" The 5D model gives you the answer in seconds. This precision removes the "guesstimate" factor and provides a mathematical foundation for your financial plan.

Accurate Market Rate Analysis

Historical data is useful, but it is dangerous if used in isolation. The cost to build a tower in 2020 is irrelevant to a construction project starting in 2026. Inflation, supply chain disruptions, and labor availability cause rapid shifts in market rates.

To create a realistic budget, you must constantly poll the market. This involves engaging with contractors and suppliers early in the process. Do not rely on generic "cost per square foot" indices found online. These are averages that do not reflect the specific complexities of your site or design.

Obtain budgetary quotes for major packages like steel, glazing, and MEP equipment. Factor in the lead times. If a chiller takes 6 months to arrive, you might need to pay a premium to air-freight it if the schedule slips. Understanding the current "temperature" of the supply chain is vital for accurate pricing.

Risk-Adjusted Costing

Every construction project carries specific risks. A site located downtown has different risks than a site in the desert. A bulletproof budget assigns a monetary value to these risks.

Perform a risk assessment workshop. Identify potential threats:

- Logistics: Will site access be restricted during rush hour? This increases delivery costs.

- Geology: Is there a risk of high groundwater? This increases dewatering costs.

- Regulatory: Is there a risk that the fire code changes before completion? This increases retrofit costs.

Assign a probability and a cost impact to each risk. If there is a 50% chance of a $50,000 delay, add $25,000 to the risk budget. This technique, known as quantitative risk analysis, ensures that you are financially prepared for the problems that are most likely to occur.

Cash Flow Management

A budget tells you how much you will spend. A cash flow forecast tells you when you will spend it. You might have the total budget secured, but if you do not have the liquidity to pay the steel supplier's deposit in Month 3, the project stops.

Construction spending is not linear. It typically follows an "S-Curve." Spending is low at the start (mobilization), spikes in the middle (structure and MEP), and tapers off at the end (finishes).

Map your budget against the construction schedule. Understand the payment terms of your major vendors. If the elevator manufacturer requires 50% upon ordering, that is a massive cash outflow early in the project. A bulletproof budget is always paired with a detailed cash flow projection to prevent liquidity crises.

Controlling Change Orders

The fastest way to destroy a budget is through uncontrolled Change Orders. These occur when the scope of work changes after the contract is signed. Contractors often bid low to win the job, planning to make their profit through aggressive change order pricing later.

To bulletproof your budget against this, you must "freeze" the design before construction begins. This requires rigorous design coordination. Ensure that the architectural drawings match the structural drawings and the MEP models. Any conflict between these documents is a Change Order waiting to happen.

Implement a strict Change Control Process. No change is approved without a signed variation order that details the cost and schedule impact. By making changes difficult and formal, you discourage scope creep and keep the construction project aligned with the original financial plan.

Vendor Qualification and Scope Gaps

The lowest bid is rarely the best bid. When you receive tenders from contractors, you must perform a "normalization" process. Contractor A might bid $1 million, and Contractor B might bid $800,000. It looks like Contractor B is the better deal.

However, a detailed review might reveal that Contractor B excluded the crane, the waste removal, and the scaffolding. Once you add these costs back in, Contractor B is actually more expensive.

A robust budget relies on thorough "scope gap analysis." You must verify that the contractor has included absolutely everything required to complete the work. Do not accept exclusions. Force the contractors to price the full scope. This prevents the unpleasant surprise of receiving invoices for "extra work" that was actually essential work.

Conclusion: Discipline Over Optimism

Optimism is necessary to start a project, but discipline is necessary to finish it. A bulletproof budget is an exercise in discipline. It rejects convenient assumptions in favor of hard data. It anticipates problems rather than ignoring them.

By utilizing detailed WBS, leveraging 5D BIM technology, and managing risks proactively, you transform the budget from a passive document into an active management tool. This financial clarity allows you to make decisions with confidence, secure in the knowledge that your construction project is built on a solid economic foundation.

Achieving this level of precision requires a partner who understands both the engineering and the economics of construction. Your BIM Partner is that resource.

We provide the technological backbone for accurate budgeting. From 5D quantity extractions to clash-free design coordination, we help you define your scope with absolute clarity. Our project management services ensure that your financial plan is executed with rigor. Do not let hidden costs undermine your investment; plan with precision and build with profit using Your BIM Partner.