In the world of manufacturing and assembly, self pierce riveting has emerged as a revolutionary technique for joining metal sheets. Unlike traditional methods, this process enables the fastening of two or more layers of material without pre-drilling holes, making it faster, cleaner, and more cost-effective. Industries from automotive to electronics are increasingly adopting this technology to enhance production efficiency while maintaining structural integrity.

What is Self Pierce Riveting?

Self pierce riveting (SPR) is a mechanical fastening method that joins materials by driving a rivet through the top sheet and forming a mechanical interlock with the bottom sheet. Unlike conventional riveting, which requires pre-drilled holes, SPR pierces the top material automatically, spreading the rivet tail to secure the layers together. This process is especially useful for materials that are difficult to weld, such as aluminum or coated steel.

Key advantages include:

-

No need for pre-drilled holes – saves time and reduces labor costs.

-

Compatible with coated or painted surfaces – avoids damage to protective finishes.

-

Strong mechanical bonds – ideal for load-bearing applications.

-

Fast and automated – suitable for high-volume production lines.

How Self Pierce Riveting Works

The SPR process involves three main steps:

-

Positioning: The materials to be joined are aligned precisely under the riveting machine.

-

Rivet Insertion: A specially designed rivet is driven at high speed through the top sheet, piercing it without cutting through the bottom sheet.

-

Forming the Joint: The rivet tail expands within the lower layer, creating a strong, permanent mechanical lock.

This process does not generate sparks or high heat, unlike welding, which makes it safer and ideal for sensitive materials and mixed-metal assemblies.

Applications of Self Pierce Riveting

Self pierce riveting is widely used across multiple industries due to its versatility and efficiency. Common applications include:

-

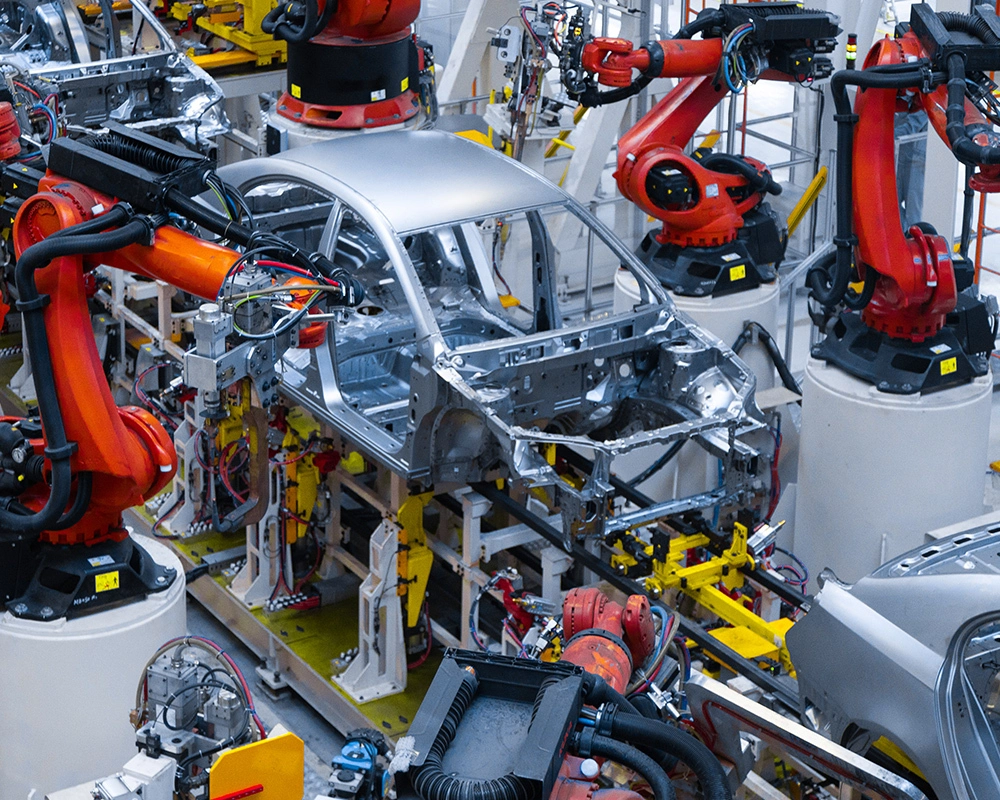

Automotive Manufacturing: Joining aluminum and steel panels in car bodies for lightweight, durable structures.

-

Electronics: Assembling casings and frames where precise fastening is required.

-

Aerospace: Creating lightweight, corrosion-resistant assemblies without compromising safety.

-

Appliances: Fastening components in household devices like refrigerators and washing machines.

The method is particularly effective for multi-material assemblies, such as aluminum to steel, where traditional welding may be ineffective or cause material deformation.

Benefits Over Traditional Methods

Compared to spot welding or mechanical fastening with screws, self pierce riveting offers several advantages:

-

Reduced Production Time: Eliminates pre-drilling and minimizes assembly steps.

-

Improved Joint Strength: Provides consistent, reliable fastening suitable for high-stress applications.

-

Cost Efficiency: Lowers labor and energy costs while minimizing waste.

-

Flexibility: Works with different metals and coatings without damaging surface finishes.

Choosing the Right Riveting Equipment

Selecting the proper SPR machine is critical for achieving optimal results. Factors to consider include rivet size, material thickness, and production speed. Automated machines offer high repeatability and precision, while manual units are suitable for smaller-scale operations or prototyping.

Conclusion

self pierce riveting is transforming how industries approach metal joining, offering a faster, safer, and more versatile alternative to traditional methods. Its ability to join dissimilar materials, maintain surface finishes, and deliver strong mechanical bonds makes it indispensable in modern manufacturing.

For businesses looking to improve efficiency and product quality, investing in self pierce riveting technology is a strategic choice. Explore professional SPR solutions to streamline your assembly process and stay ahead in competitive markets.

Call to Action:

Upgrade your manufacturing process today by adopting self pierce riveting technology. Discover the latest machines, rivets, and expert solutions that ensure strong, efficient, and reliable metal joining for your production line.