In today's competitive manufacturing world, ensuring the strength and reliability of materials is more important than ever. Whether you're in the packaging, textile, or paper industry, a Bursting Strength Tester is a vital piece of equipment that helps maintain quality standards and customer satisfaction.

What is Bursting Strength?

Bursting strength refers to the amount of pressure a material can handle before it breaks or bursts. This measurement is crucial for materials that face handling, stacking, and transport stresses—such as cardboard boxes, fabric rolls, and paper products.

With a Bursting Strength Tester, manufacturers can evaluate how much force a sample can resist. This simple yet powerful test reveals how durable a material is and helps prevent failures in real-world applications.

How the Tester Works

The Bursting Strength Tester works by applying uniform pressure to a sample via a rubber diaphragm. As the pressure increases, the sample eventually bursts. The pressure at that breaking point is recorded as the material’s bursting strength.

This test mimics real-world conditions and provides valuable insight into the durability of your products—before they leave the factory floor.

Key Features

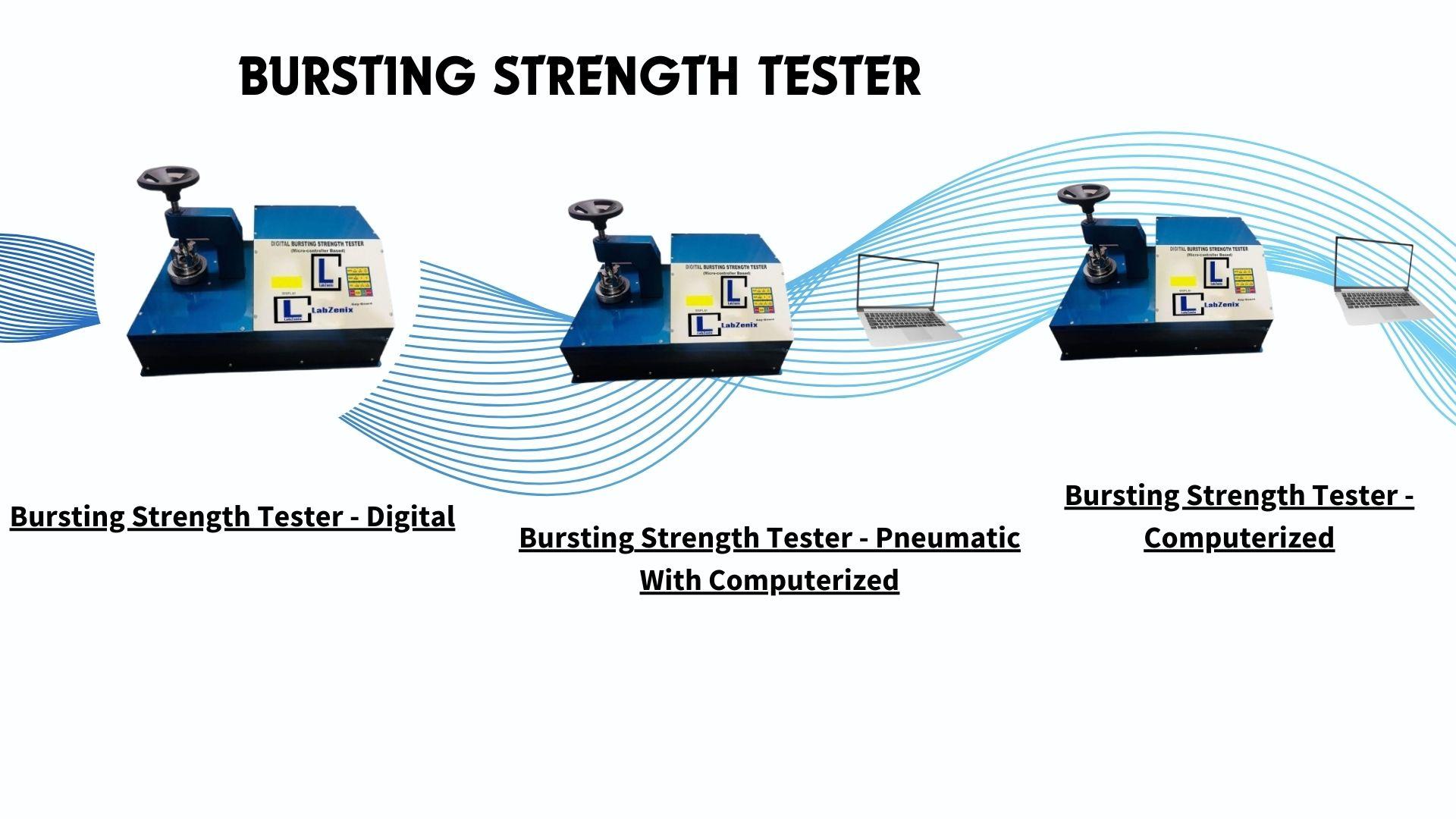

Modern Bursting Strength Testers come packed with features that enhance performance and ease of use:

-

Digital display for accurate, instant readings

-

Adjustable pressure levels to suit different materials

-

User-friendly interface for quick and smooth operation

-

Durable design ideal for long-term industrial use

-

Consistent performance for reliable quality control

Where It’s Used

1. Packaging Industry

Cardboard boxes and shipping cartons must hold up during transport. Bursting tests ensure they won’t fail under pressure.

2. Paper Industry

From tissue paper to paperboard, consistent strength is key. Testing helps maintain uniform quality across batches.

3. Textile Industry

Fabrics used in clothing, upholstery, and industrial applications must resist tearing and stress. Bursting strength confirms their resilience.

4. Nonwoven Products

Medical and hygiene materials demand high durability. This test helps ensure they meet safety and performance standards.

5. R&D and Quality Labs

During product development, strength testing Price helps refine materials before full-scale production begins.

Why It Matters

-

✅ Ensures product durability

-

✅ Prevents costly failures or recalls

-

✅ Helps meet international quality standards

-

✅ Boosts brand reliability and customer trust

Final Words

At Labzenix.com, we understand the importance of quality control. Our Bursting Strength Testing are engineered to deliver precise results with maximum efficiency. Whether you're improving product reliability or complying with standards, this tool is a smart investment for your production line.